Introduction to CNC Machining: Understanding the Basics

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools. This technology has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with minimal human intervention. For beginners, understanding CNC machining involves exploring what it is, how it works, and its diverse applications across various industries.

What is CNC Machining?

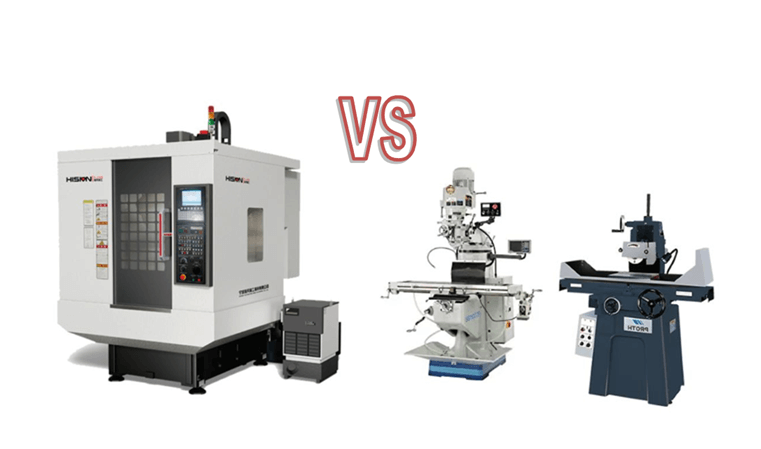

CNC machining is a subtractive manufacturing process where material is removed from a solid block (or workpiece) to create a desired shape. The process is controlled by a computer that interprets a digital design file and translates it into specific commands to control machine tools. These tools can include lathes, mills, routers, grinders, and more.

How Does CNC Machining Work?

- Design and Software: The process begins with creating a digital design of the part using Computer-Aided Design (CAD) software. This design is then converted into a Computer-Aided Manufacturing (CAM) file, which outlines the tool paths and operations needed to produce the part.

- Programming the CNC Machine: The CAM file is translated into G-code, the programming language that CNC machines understand. G-code consists of a series of commands that direct the machine’s movements, speed, and tool changes.

- Setup: The workpiece is secured to the machine’s worktable, and the appropriate cutting tools are installed. The machine is then calibrated to ensure precision during operation.

- Machining: The CNC machine follows the G-code instructions to perform the required operations. This can include cutting, drilling, milling, and turning. The machine removes material layer by layer to achieve the final shape.

- Inspection and Finishing: After machining, the part is inspected for accuracy and quality. Additional finishing processes, such as sanding, polishing, or coating, may be applied to achieve the desired surface finish.

Key Components of a CNC Machine

- Control Unit: The brain of the CNC machine, the control unit interprets G-code and sends signals to the machine’s components.

- Machine Tool: The device that performs the actual cutting, shaping, or drilling of the material.

- Worktable: The platform where the workpiece is secured during machining.

- Spindle: The part of the machine that holds and rotates the cutting tool.

- Motors and Drive Systems: Responsible for moving the machine components along different axes.

Applications of CNC Machining

CNC machining is widely used across various industries due to its precision, repeatability, and ability to produce complex geometries. Some common applications include:

- Aerospace: Manufacturing high-precision components such as engine parts, turbine blades, and structural components.

- Automotive: Producing parts like engine blocks, transmission components, and custom car parts.

- Medical: Creating medical devices, implants, and surgical instruments with high precision and quality.

- Electronics: Fabricating enclosures, connectors, and other intricate parts for electronic devices.

- Consumer Goods: Manufacturing custom-designed products, prototypes, and parts for household appliances and tools.

Benefits of CNC Machining

- Precision and Accuracy: CNC machines can produce parts with tight tolerances and high consistency.

- Efficiency: Automation reduces the time and labor required for manufacturing.

- Flexibility: CNC machines can be reprogrammed for different tasks, making them versatile for various production needs.

- Safety: Reduces human involvement in potentially hazardous machining operations.

Conclusion

CNC machining is a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility. For beginners, understanding the basics of CNC machining opens up a world of possibilities in various industries. As technology continues to advance, the capabilities of CNC machining will expand, further transforming how we design and produce complex parts and products.